BMW, Figure Collaborate to Deploy General-Purpose Robots.

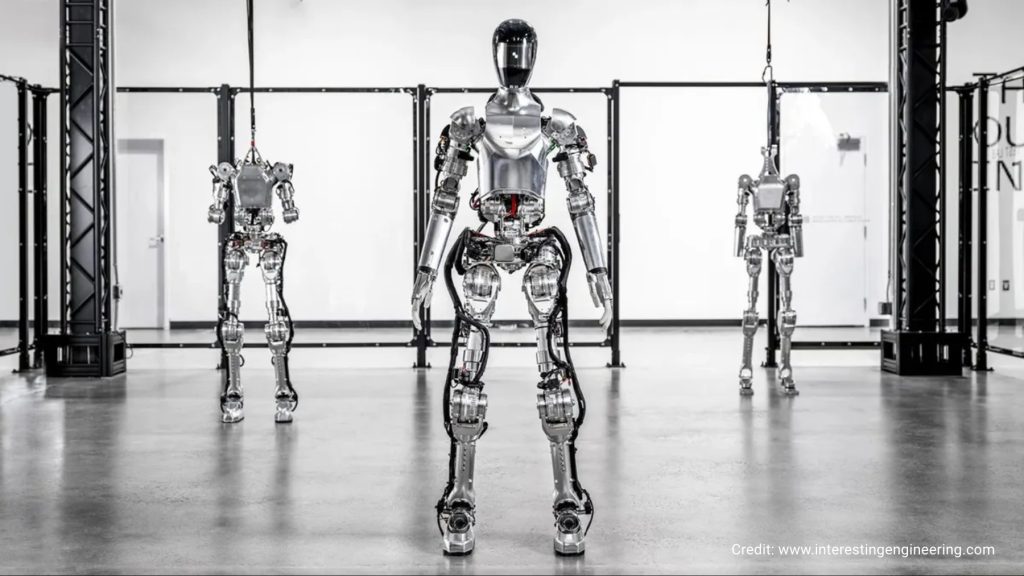

BMW, Figure Collaborate to Deploy General-Purpose Robots. BMW has signed an agreement with Figure, a Silicon Valley-based autonomous robotics company, to deploy their general-purpose humanoid robots in Spartanburg factory, BMW’s largest manufacturing facility in the US.

General-Purpose Robots

Humanoid robots are utilized for hazardous and repetitive tasks, such as box-moving, pick-and-place operations, and loading or unloading. With this initiative, BMW is prioritizing the well-being of human workers, focusing not on replacing humans with robots but on having them assist and collaborate with human labor. BMW aims to accelerate its workflow with an error-free methodology, reducing the risk of accidents. The ability to reprogram these robots for different tasks is a crucial asset for BMW.

The humanoid robots are based on a general-purpose design. They are flexible and adaptable to a variety of tasks, depending on their design and programming.

“Single-purpose robotics have dominated the commercial market for decades, but the potential of general-purpose robotics is completely untapped. Figure’s robots will enable companies to increase productivity, reduce costs, and create a safer and more consistent environment,” said Brett Adcock, founder and CEO of Figure.

Although it has been around two weeks since the date of the agreement, the deployment is in its initial phase, and there is no specific timeline for the large-scale deployment of humanoid robots. The testing phase serves several purposes: minimizing risks, addressing challenges before wider deployment, ensuring flexibility and adaptability for adjustments in response to sudden circumstances, and, most crucially, data collection.

Data collection occurs in the first stage of deploying the robots, out of two stages, for future development and optimization, underscoring the importance of a staged approach for such agreements.

- Stage One: Identifying Use Cases

This stage requires collaboration between engineers from BMW and Figure to analyze the workflow process and the interactions of the workers, potentially focusing on safety considerations. The aim is to select certain tasks as aforementioned, like the repetitive ones to give space to more complex and valued activities for the human workers.

- Stage Two: Testing the Deployment

After the first stage, where suitable cases for robot deployment are identified, monitoring a small number of robots in targeted fields begins to assess their performance and collect data. Once the robots’ performance is deemed successful, the deployment phase may be gradually expanded to include other areas and tasks beyond the initial targets. This allows for the adaptation of the robots to be programmed and refined based on real-world experiences.

“The automotive industry, and with it the production of vehicles, is evolving rapidly,” said Robert Engelhorn, president and CEO of BMW Manufacturing, in a statement. “The use of general-purpose robot solutions has the potential to make productivity more efficient, support the growing demands of our consumers, and enable our team to focus on the transformation ahead of us.”

About Figures

The BMW-Figure partnership at the Spartanburg factory represents a unique collaboration, with Figure having been founded in 2018 by engineers from Google, Apple, and other tech companies. It focuses on developing AI-powered robots capable of learning and adjusting to new situations, having raised over $200 million in funding from investors, including SoftBank and Andreessen Horowitz.

Inside Telecom provides you with an extensive list of content covering all aspects of the tech industry. Keep an eye on our Intelligent Tech sections to stay informed and up-to-date with our daily articles.